NetVia Group - an Epec Company

For more than 35 years, the most advanced and innovative technology companies have relied on NetVia Group for all their time-critical, high performance PCB solutions. In 2019, NetVia Group became a part of the Epec Engineered Technologies group of companies, which continue to hold true to the values of excellence that have driven NetVia since the beginning.

Epec Engineered Technologies is the ideal choice for an OEM seeking customized solutions from a focused and agile partner having supported more than 5,000 customers across all sectors of the electronics industry.

By providing highly experienced technical resources, a proven manufacturing platform, and the fastest delivery in the industry, we are able to provide cost-effective and innovative solutions that deliver the highest reliability products to the market faster.

Contact us today to learn how we can help you with all your PCB needs.

Equipment Investments

One of our core values is to reinvest heavily into our equipment, software, and people to ensure that we can continue to deliver the highest technology PCBs in North America. This NEW equipment optimizes NetVia Group’s processing and production capabilities, which puts our customers in a position to keep up with the increasing demands of the electronics industry.

Some of our investments include:

- Six drill machines, up to 300K/RPM spindles for mechanical drilling uVias (0.004" diameter)

- Laser Drill for flex, rigid-flex, and microvia PCB manufacturing

- CCD drilling and routing capability for higher precision as well as backdrill depth control

- Pneumatic via fill to improve speed, quality, and consistency of via fill process

- Tool less Inkjet silkscreen printing

- X-ray fluorescence metallurgical analysis

- Automated planarization equipment to enable tighter control of copper removal during the process

- Reverse Pulse Plating for high aspect ratio and uniform plating consistency on surfaces and holes

- New flying probe tester for additional capacity and redundancy

- In pursuit of our quality goals, Netvia Group continues to invest heavily in equipment and training

Our Advanced Array of Equipment

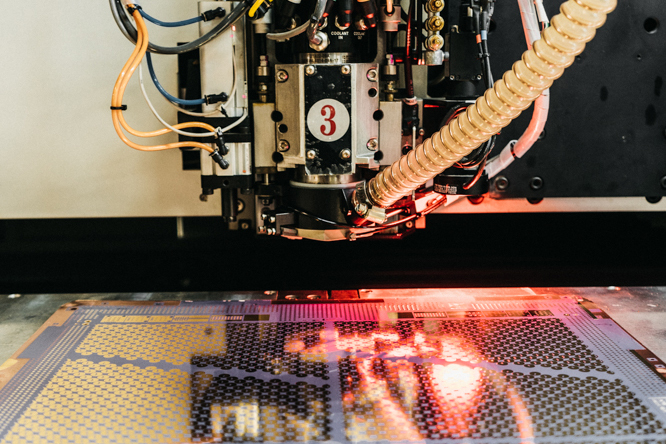

- DLG 2+2 High Accuracy Drills:

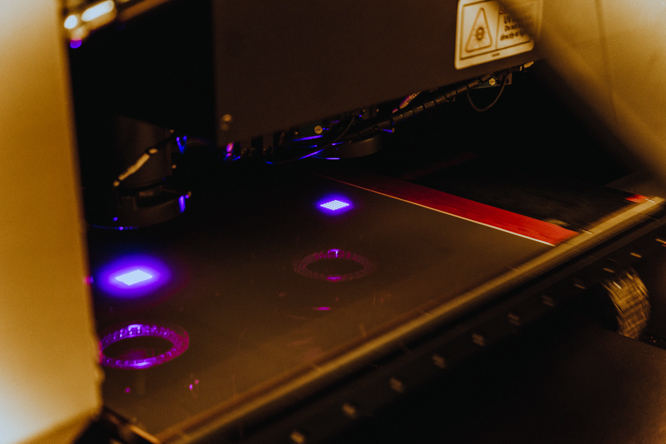

With its precision German machining and craftsmanship, high speed linear motors, advanced pressure foot system, high-capacity tool changing system, and industry leading camera and optical registration capabilities, the DLG 2+2 provides better precision, accuracy, hole wall quality, and controlled depth drilling capabilities than competing systems. The industry-leading 300,000 rpm high speed spindles enables mechanical micro drilling down to a 0.003” bit diameter. Using advanced layer detection and controlled depth capabilities, the DLGs will mechanically drill blind vias, allowing for a single set up, optimal registration, and better hole formation for the subsequent metallization and plating processes. The high-resolution digital camera system can be used not just for surface feature detection, but for inner layer inspection and registration data collection. The camera will investigate the inner layers and use that data to calculate optimal offset, rotation, and scale for the complete panel. That data is then fed back into our scale prediction database and control software, creating a feedback loop for continuous improvement of the drilling process. Ultimately this means better yields, faster production, and higher quality fabrication results for our customers. At the high end of the market that NetVia competes in, we know we must fight for every thousandth of an inch, and our equipment, our people, our procedures, and our training have to work together to achieve exceptional results for our customers. - ESI 5335/Laser Drill:

The ESI 5335 delivers industry leading capabilities for UV laser via drilling/cutting and is optimized for processing both flex and rigid-flex PCBs. The laser system also addresses other high accuracy applications such as routing, patterning, and skiving, which is achieved through a combination of a compound beam and solid-state optical technology. - TRM-422 / Four Spindle Router:

Equipped with CCD cameras, Laser Tool Check, Real Time Broken Bit Detection, and Four 60K Spindles. - SDL-620 / Six Spindle Drill:

Equipped with CCD cameras, Laser Tool Check, Real Time Broken Bit Detection, and Six 60K Spindles. - Micro Vu Excel 661UC Precision Measurement System:

This Automated Precision Measurement System allows NetVia Group to perform high-precision 2D and 3D measurements. No more calipers or pin gauges as the Micro Vu accurately measures line width etch, drill, image position, and profiles down to 0.15 mils. This means more accurate AS-9102 Inspections and First Article Inspections for our customers. The multisensor capabilities, advanced digital and optic zoom, proprietary edge detection, and InSpec Metrology Software allows NetVia Group to maintain its industry lead in quality fabrication of printed circuit boards. - Advanced Multi-head DI/Laser Direct Imaging:

This system bypasses the traditional process of PCB manufacturing that requires photoplots or film in order to reproduce the circuit image onto the substrate. It also eliminates the common defects associated with film instability, nicks, cuts, and de-formation of the image. With the addition of the LDI, we now have the ability to expose directly onto the substrate at a higher image resolution and with automated real time scaling on every panel produced.

Additional Equipment:

- Orbotech Discovery II 8800 AOI

- Glenbrook X Ray machine

- DP 1500 Screen Printer

- Microcraft EMMA E4M6151 flying probe electrical testing

- Handheld Cu thickness measurement

- High resolution microscopic cross section image capture

- Orbotech Genesis 2000 CAM stations

- HC-2000 Hole Inspector

- Pola Massa PEM650 / Automated Planarization Line

- Orbotech Sprint 150 / Inkjet Legend Printer + LED Exposure System

- Wise Stripstar / Horizontal Resist Strip Line with thin core capability

- Wise Chemstar / Horizontal Tin Strip Line with thin core capability

- Wise Chemstar / Horizontal Chemical Clean Line with thin core capability

- IPS Reverse Pulse Plate / High Aspect Ratio and Computer Controlled Electroplate Copper

- Lenz CCD smart drill with auto-loader

- Multiline Technology OPE / Automated Post Etch Punch

- Glennbrook X-Ray

- Dynachem 1600v / Automatic Dry Film Cut Sheet Laminator

- Circuit Automation DP-1500 / semi-automatic soldermask printer

- Bowman B Series XRF

- Buck Scientific 230 ATS

Looking for Rigid PCBs, Flex Circuits, or Rigid-Flex Circuit Boards?

We are positioned to move quickly to produce the most advanced PCBs available in the circuit board industry.

Request a Quote Today!