PCBs For The Aerospace and Defense Industries

When it comes to the high-reliability aerospace and defense industry, the printed circuit boards (PCBs) used in electronic systems must meet strict requirements for performance, durability, and reliability. NetVia Group is a leading provider of PCB solutions for the industry, offering a range of services that are specifically tailored to the unique needs of aerospace and defense applications.

High-Reliability Printed Circuit Boards

High-reliability printed circuit boards have come to define NetVia Group. Our customer list includes some of the biggest companies in the military and aerospace industry and they keep coming back to NetVia due to our service, quality, and our experience in understanding the complexity of PCBs that go into these applications.

Below are some reasons why NetVia Group is the best solution for printed circuit boards for the high-reliability aerospace and defense industry.

Material Experience

NetVia Group has extensive experience in working with a wide range of materials that are commonly used in the aerospace and defense industries. This includes high-temperature laminates, polyimide, Rogers, Tachyon, and other advanced materials that are capable of withstanding extreme conditions, such as high altitude, temperature, and pressure.

Our team of experts has a deep understanding of the properties and characteristics of these materials, which allows them to select the best material for a particular application and ensure that the PCB meets all necessary requirements for performance and reliability. As well as having experience, we have a significant amount of material in stock in order to allow us to move quickly to produce circuit boards for our customers.

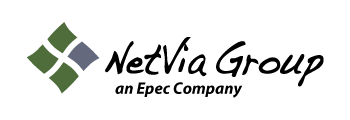

High PCB Layer Count Capability

NetVia Group has a high PCB layer count capability, meaning that it can manufacture circuit boards with a large number of layers. This is particularly important for aerospace and defense applications, as these systems often require complex PCBs with many layers to accommodate the necessary components and functionality. Our high layer count capability and 20+ years of experience, allow us to manufacture PCBs that meet these requirements while still maintaining a high level of quality and reliability.

Equipment Investment

NetVia Group has made significant investments in state-of-the-art equipment and technology to ensure that they can provide the best possible PCB solutions for aerospace and defense applications. This includes advanced manufacturing equipment, such as laser drilling machines, laser direct imaging equipment, the latest plating, and via-fill technology, which allow us to create precise, high-quality PCBs with complex features such as blind/buried vias. Our commitment to investing in the latest technology ensures that we will continue to be able to produce the highest level of quality and reliability in our printed circuit boards.

PCB Testing Capabilities

One of the most important aspects of ensuring the reliability of PCBs for aerospace and defense applications is rigorous testing. NetVia Group has a comprehensive in-house microsection lab and testing program that includes both automated and manual testing methods to ensure that every PCB they manufacture meets the necessary standards for performance and reliability.

This includes in-house testing as well as third-party testing (when required) to ensure that the PCBs can withstand the most extreme conditions and environments.

Blind/Buried Vias

Blind/buried vias are a critical component of many aerospace and defense PCBs. These vias are used to connect different layers of the circuit board without passing all the way through the board, which allows for a more compact and efficient design. We have extensive experience in manufacturing PCBs with blind/buried vias, and our advanced equipment and technology allow them to create these features with a high level of precision and accuracy.

Heavy Copper Circuit Boards (up to 5 oz)

Heavy copper is another critical component of many aerospace and defense circuit boards. These PCBs require thicker copper layers to support higher currents, which can be challenging to manufacture. NetVia Group has the experience and equipment necessary to manufacture PCBs with heavy copper layers up to 5 oz, ensuring that the PCBs can handle the necessary current loads while still maintaining a high level of reliability and performance.

Laser Drilling

Laser drilling is a key technology for manufacturing complex PCBs for aerospace and defense applications. This technology allows for precise, high-quality drilling of small holes and vias, which is critical for creating PCBs with a high layer count, blind/buried vias, and other complex features. We have made significant investments in laser drilling technology, ensuring that we are able to manufacture parts that require micro vias for our high-reliability military and aerospace customers.

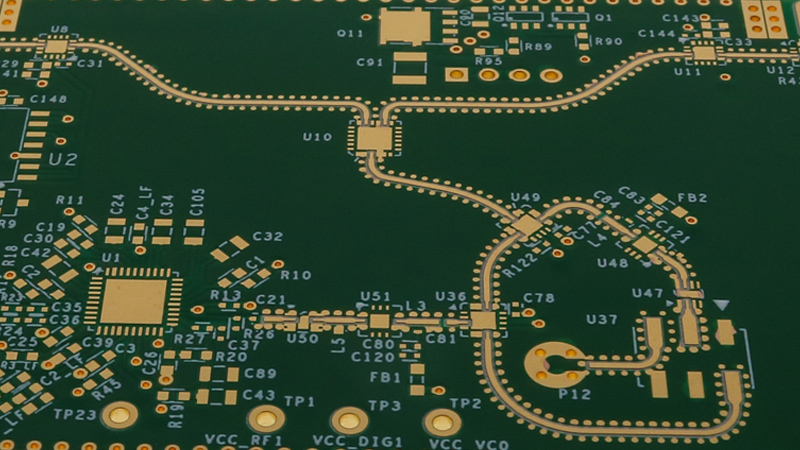

Flex and Rigid-Flex PCBs

NetVia Group's capabilities extend beyond traditional rigid PCBs, as we are also able to produce flexible and rigid-flex circuit boards for high-reliability mil-aero applications. These types of PCBs are particularly well-suited for applications where space is limited, and where the PCB must be able to bend or flex without compromising performance or reliability.

Our experience with advanced materials and manufacturing techniques, as well as our commitment to rigorous testing, quality control, and investment in the newest equipment sets, make us an ideal partner for producing flex and rigid-flex PCBs for the most demanding mil aero applications.

Certifications

As we have been servicing Tier One defense and aerospace customers for many years, we are very familiar with all the different specifications that apply to printed circuit boards. We can build and test products that comply but are not certified to, MIL-55110, MIL-31032, and AS-9100. See our blog post on IPC Class III vs. MIL Spec for Printed Circuit Boards to get more information about how we can produce parts in compliance with the standards.

In addition to IPC-6012/6018 Space Addendum and/or class 3, NetVia Group also caters to individualized requirements set forth by our clientele, which can include 3rd party lab verification, data/coupon retention, lot traceability, source inspection, key characteristic measurements taken while in process and many others flowed down quality requirements. We are also JCP, DD2345 certified.