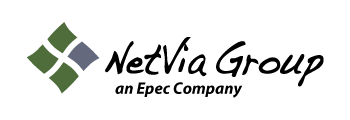

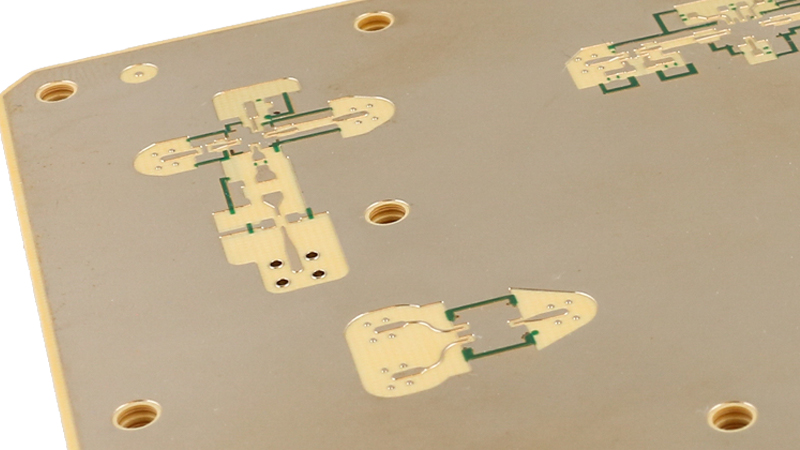

Microwave/RF Printed Circuit Boards

At Netvia Group, we work hard to be the premier destination for manufacturing high-quality microwave/RF printed circuit boards (PCBs). With our specialized processes, state-of-the-art equipment, extensive inventory of key laminates, and years of experience, we are the best option for fulfilling your PCB manufacturing needs for these critical applications.

Expertise and Specialized Processes

Given our many years of experience, NetVia Group understands the unique requirements of microwave/RF PCBs and has developed specialized processes to ensure optimal performance and reliability. Our team of experienced engineers and technicians possess in-depth knowledge of high-frequency design principles, impedance control, signal integrity, and EMI/EMC considerations.

Our manufacturing processes include precise etching techniques, controlled impedance routing, and microvia drilling, all performed with the utmost attention to detail. We use advanced equipment, such as laser direct imaging (LDI) systems and automatic optical inspection (AOI) machines, to achieve exceptional precision and quality control throughout the production process.

State-of-the-Art Equipment

To meet the demanding requirements of microwave/RF PCBs, we have invested in cutting-edge equipment that enables us to deliver superior products. Our manufacturing facility houses state-of-the-art CNC machines, capable of producing intricate features and fine traces with utmost accuracy.

We utilize laser drilling systems, with beam sizes as small as 20 microns, to create high-density microvias, allowing for efficient signal transmission and reduced parasitic capacitance. Our state-of-the-art plating lines ensure uniform copper deposition, even in complex geometries, providing excellent signal integrity. Along with our significant investment in Laser Direct Imaging equipment which allows us to consistently produce line width and spacing to the exacting tolerances of this application.

Understanding and Inventory of Key Laminates

Selecting the right laminate material is crucial for the performance and reliability of microwave/RF PCBs and we have an extensive understanding of the key laminates used in these applications. We work closely with industry-leading laminate manufacturers, such as Rogers Corporation, Isola, and Taconic Advanced Dielectric Division, to source the highest quality materials.

Our inventory includes a wide range of laminates with excellent dielectric properties, low loss tangent, and high thermal conductivity, suitable for high-frequency applications. Whether you require materials with specific Dk (dielectric constant) values, low moisture absorption, or controlled expansion properties, we have the expertise to guide you in choosing the ideal laminate for your needs.

Some of the most common laminate materials are:

- Rogers RO4000 Series, such as RO4350B and RO4003C. These laminates have low loss tangents, excellent stability of dielectric constant over a wide frequency range, and good temperature performance.

- Rogers RO3000 Series, including RO3003 and RO3010. These laminates offer lower dielectric loss and improved thermal stability compared to FR-4.

- Taconic TLY Series, such as TLY-5 and TLY-6. These laminates have low loss tangents, excellent dimensional stability, and good electrical properties across a wide frequency range.

- Isola IS680 Series, including IS680-338 and IS680-370. These laminates offer low loss, excellent thermal performance, and stable electrical properties over a wide frequency range.

- I-Tera MT: The I-Tera MT laminate is a high-speed material designed for applications demanding extremely low loss and low skew. It offers excellent electrical properties, including low dielectric constant and low loss tangent, making it suitable for high-frequency designs.

- Tachyon laminate is a very low-loss material designed for high-speed digital applications beyond 100 Gb/s. This Isola material has excellent electrical properties and is very stable over a broad frequency and temperature range. It has a dielectric constant (Dk) of 3.02, dissipation factor (Df) of 0.0021, and is stable at temperatures from -55°C and +125°C up to 40 GHz.

- Megtron is a high-performance laminate developed by Panasonic for use in high-speed and high-frequency applications. It is a glass-reinforced hydrocarbon/ceramic material known for its excellent electrical properties, mechanical stability, and signal integrity. Megtron laminates are widely used in the design and manufacturing of high-speed digital and microwave/RF PCBs.

Experience in Manufacturing Microwave/RF PCBs

With over 20 years of experience in manufacturing microwave/RF PCBs, NetVia Group has built a solid reputation for delivering exceptional products and exceeding customer expectations. Our track record of successful projects in various industries, including aerospace, telecommunications, and defense, showcases our expertise in this specialized field.

We take pride in our commitment to quality, adhering to rigorous quality control standards throughout the manufacturing process. Our facility is ISO 9001 certified, ensuring that every PCB we produce undergoes comprehensive inspection and testing to guarantee compliance with the highest industry standards.

Furthermore, we understand the importance of on-time delivery and offer flexible manufacturing options to meet your project deadlines. Our efficient production processes, combined with our dedicated project management team, enable us to deliver your PCBs promptly without compromising on quality.

Choose The Netvia Group for Unmatched Microwave/RF PCB Manufacturing

When it comes to microwave/RF PCB manufacturing, Netvia Group stands out as the best option for customers seeking exceptional expertise, quality, and reliability. Our specialized processes, state-of-the-art equipment, extensive inventory of key laminates, and years of industry-specific manufacturing experience have created the best solution for success for our customers.