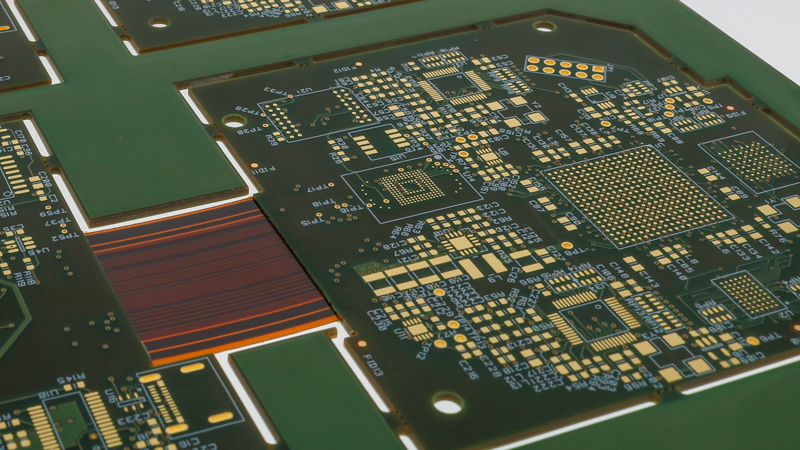

Flex & Rigid-Flex Printed Circuit Boards

NetVia Group, is a leading manufacturer of high-quality flex and rigid-flex printed circuit boards (PCBs) from our facility located outside of Dallas, Texas. With our state-of-the-art facilities, advanced technology, and a team of experienced professionals, we offer comprehensive capabilities in the production of flex and rigid-flex PCBs.

Expertise in Flex and Rigid-Flex PCBs

We take pride in our deep expertise in flex and rigid-flex PCBs. Our dedicated team of engineers and technicians have years of experience in designing, manufacturing, and testing flexible circuits. We understand the unique challenges and requirements associated with flex and rigid-flex PCBs, and we leverage our knowledge to deliver outstanding results.

Material Selection

Selecting the right materials is critical for the performance and durability of flex and rigid-flex PCBs. At NetVia, we have established strong partnerships with reputable material suppliers such as Dupont and Panasonic to ensure access to a wide range of high-quality materials suitable for flexible circuits. Our experts guide you through the material selection process, considering factors such as flexibility, thermal management, signal integrity, and environmental considerations.

Prototyping and Testing

We understand the importance of prototyping and testing in the development of reliable flexible circuits and rigid-flex circuit boards. We offer rapid prototyping services, allowing you to validate your design before moving into full-scale production.

Manufacturing Capabilities

Our state-of-the-art manufacturing facilities are equipped with the latest technology and equipment. We have invested heavily in advanced machinery, including precision laser drilling and cutting systems, laser direct Imaging, and high-accuracy inspection equipment. Our manufacturing capabilities enable us to handle projects of various sizes and complexities, ensuring consistent quality and timely delivery.

We have invested heavily in our equipment including:

- Laser Drilling and Cutting Systems: Flex and rigid-flex PCBs often require precise drilling and cutting of the flexible substrate. Laser drilling systems utilize high-powered lasers to create small holes in the substrate material, allowing for the placement of components and interconnections. Laser cutting systems are used to precisely cut and shape flexible circuits according to the required design.

- High-Accuracy Inspection Equipment: Advanced imaging equipment, such as automated optical inspection (AOI) systems and X-ray inspection machines, are used for quality control and inspection purposes. AOI systems capture detailed images of the PCBs, allowing for visual inspection and detection of defects like shorts and opens on very fine line designs.

- Laser Direct Imaging (LDI): This is a technology used in the production of flexible PCBs to precisely and efficiently create circuit patterns on the flexible substrate. LDI eliminates the need for traditional photolithography processes, where photomasks are used to transfer the circuit pattern onto the substrate. Instead, LDI directly exposes the circuit pattern onto the substrate using a laser system, offering several advantages in flexible PCB manufacturing:

- High Precision: LDI systems provide exceptional precision and accuracy in creating fine circuit features on flexible substrates. The laser beam focuses on specific areas, allowing for intricate and precise circuit patterns, especially in complex designs with tight tolerances.

- Alignment Flexibility: Flex and rigid-flex PCBs often require alignment flexibility due to the bending and folding nature of the substrates. LDI systems offer excellent alignment capabilities, enabling accurate registration of circuit patterns on different layers of the flexible substrate, even with complex multi-layer designs.

- Faster Production: Compared to traditional photolithography processes, LDI significantly reduces the overall production time. It eliminates the need for creating and aligning photomasks for each circuit layer, streamlining the manufacturing process and increasing efficiency.

- Improved Yield and Quality: LDI systems offer excellent process control, leading to improved yield and higher-quality flexible PCBs. The direct exposure method reduces the risk of errors caused by misalignment or damage to photomasks. It also minimizes issues related to contamination or degradation of the masks, resulting in more reliable and consistent circuit patterns.

- Environmentally Friendly: LDI eliminates the need for chemical processes used in traditional photolithography, making it an environmentally friendly option. It reduces the use of hazardous chemicals, waste generation, and disposal concerns associated with conventional processes.

Quality Assurance and Certifications

Quality is at the forefront of everything we do at NetVia. We adhere to strict quality control measures throughout the manufacturing process, from initial design to final product inspection. Our commitment to quality has earned us industry certifications, such as ISO 9001 and IPC standards compliance, reflecting our dedication to delivering reliable and defect-free flex and rigid-flex PCBs.

Applications and Industries

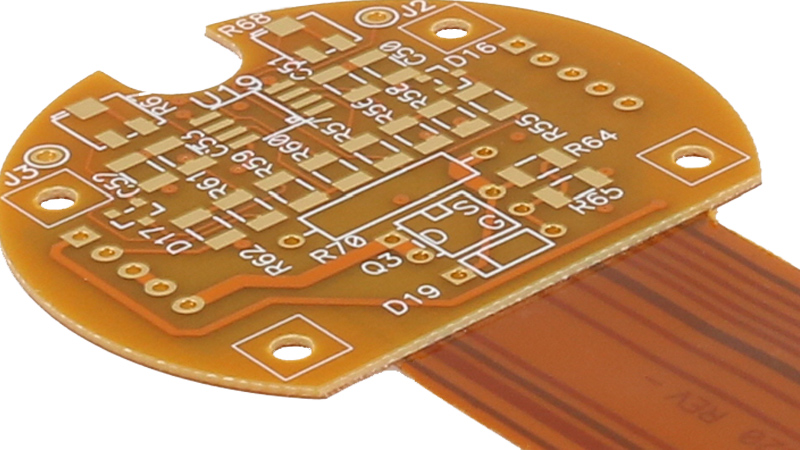

Flex and rigid-flex PCBs find applications across a wide range of industries, and NetVia caters to diverse sectors. Our capabilities extend to industries such as aerospace, automotive, medical devices, telecommunications, consumer electronics, and more. Whether you require flex circuits for compact wearable devices or rigid-flex PCBs for rugged applications, we have the expertise to meet your specific industry.

Improving PCBA Assembly Yields

One of the primary challenges in rigid-flex PCB assembly is ensuring high yields during the manufacturing process. The complex nature of rigid-flex boards, with their combination of rigid and flexible sections, demands precise alignment and secure fixation to avoid misalignment, stress, or damage. This is where we step in, providing a comprehensive solution to streamline the design and assembly workflow.

By leveraging our experience, contract manufacturers work with our engineering team to design arrays and fixtures that offer accurate positioning and alignment of rigid-flex PCBs during assembly. This facilitates the creation of custom arrays with precise locations for individual PCBs, ensuring consistent alignment of components and eliminating the potential for errors caused by manual handling.

With NetVia’s assistance, contract manufacturers can achieve higher assembly yields on rigid-flex PCBs, resulting in improved overall production efficiency and quality. The precise alignment and secure fixation provided by the designed arrays and fixtures minimize the chances of misalignment, component damage, or reliability issues. Ultimately, this leads to reduced production costs, increased throughput, and enhanced customer satisfaction.