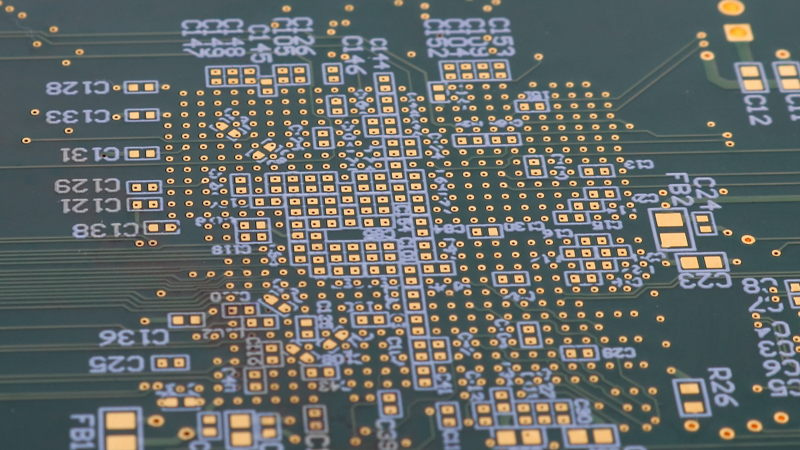

Quick-Turn High-Tech Printed Circuit Boards

Empowering Innovation Through Rapid PCB Manufacturing

In today's fast-paced technological landscape, where innovation drives success, time is of the essence. When it comes to high-tech printed circuit boards (PCBs), quick turnarounds are crucial to meet tight deadlines and stay ahead of the competition. NetVia Group is proud to be your number one choice for rapid PCB manufacturing. With cutting-edge technologies, exceptional expertise, and an unwavering commitment to customer satisfaction, we enable you to bring your ideas to life faster than ever before.

Unparalleled Speed and Efficiency

At NetVia Group, we understand the urgency of your projects and the need for rapid turnaround times. We have invested heavily in state-of-the-art facilities and advanced manufacturing processes to streamline every step of the PCB production cycle. Our automated CAM and planning departments along with optimized workflows ensure maximum efficiency, minimizing lead times without compromising quality.

Our highly skilled engineers and technicians leverage their deep industry knowledge to expedite the manufacturing process. With their expertise, they can quickly identify potential issues, suggest design improvements, and troubleshoot any challenges that may arise, ensuring smooth and fast production.

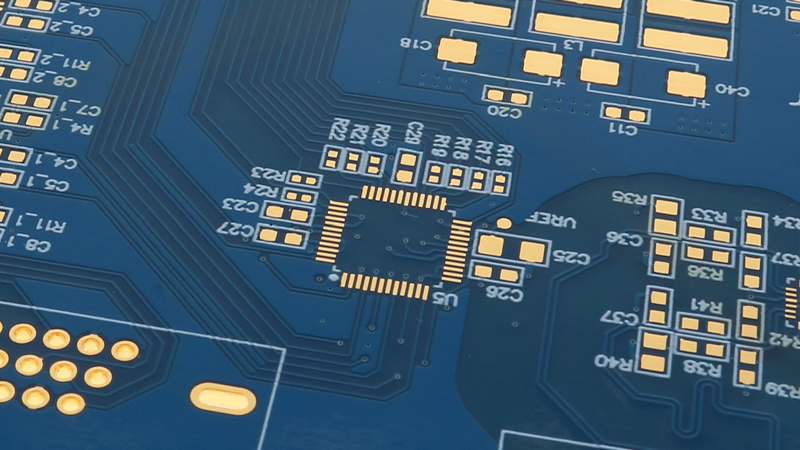

Cutting-Edge Technologies

To maintain our position as the industry leader in quick-turn PCBs, we continuously invest in the latest cutting-edge technologies. Our advanced machinery, including high-precision laser drills, automated optical inspection systems, and state-of-the-art laser direct imaging (LDI) equipment, enables us to achieve exceptional accuracy and reliability.

Moreover, our extensive range of capabilities allows us to accommodate a wide variety of design requirements, including complex multilayer PCBs, high-density interconnects (HDI), RF/microwave, and flexible or rigid-flex PCBs. We have the tools and expertise to handle the most demanding projects, all while maintaining rapid turnaround times.

Quality without Compromise

While speed is paramount, we never compromise on quality. At NetVia Group, we follow rigorous quality control processes at every stage of PCB manufacturing. Our dedicated quality assurance team meticulously inspects each board to ensure it meets the highest standards of performance, durability, and reliability.

We understand that your reputation is on the line, and we take pride in delivering products that exceed expectations. By utilizing advanced testing methodologies, including automated optical inspection (AOI) and flying probe electrical testing, we can identify and rectify any potential issues, ensuring the final product functions flawlessly.

Superior Customer Support

At NetVia Group, we prioritize customer satisfaction above all else. We believe that open communication and collaboration are vital for success. From the moment you reach out to us, our dedicated customer support team will work closely with you to understand your specific requirements, project timelines, and technical challenges.

We provide personalized guidance throughout the entire manufacturing process, ensuring transparency and keeping you informed at every step. Our team is always available to address any concerns or questions you may have, ensuring a smooth and hassle-free experience.

Industry-Leading Turnaround Times

One of the key factors that sets us apart is our industry-leading turnaround times. We recognize that time-to-market is crucial for your success, and we are committed to delivering your PCBs with unmatched speed. Our optimized processes and efficient workflows enable us to provide quick turns without compromising quality or performance.

Whether you need prototypes, low-volume production, or high-volume manufacturing, we have the capacity and capability to meet your demands. We work diligently to ensure that your PCBs are manufactured and delivered on time, empowering you to stay ahead of the competition.

Standard Lead Time = 20 Working Days

| Technology | 1 Day | 2 Day | 3 Day | 5 Day | 7 Day | 10 Day |

|---|---|---|---|---|---|---|

| 1-4 Layers | X | X | X | X | X | X |

| 6-10 Layers | X | X | X | X | X | |

| > 10 Layers | X | X | X | X |

What Are Some Of The Attributes That Affect Lead Time?

Several specific attributes can significantly affect the lead time for high-tech PCBs. Understanding these factors is crucial for effectively managing expectations and optimizing production timelines. Here are some key attributes that impact lead time:

PCB Complexity:

The complexity of a PCB design directly influences the lead time. More intricate designs, such as multilayer PCBs, high-density interconnects (HDI), several sets of blind or buried via’s, filled or plated shut via’s, or rigid-flex PCBs, require additional manufacturing steps and specialized processes. The time required for fabricating and assembling complex PCBs is generally longer than that for simpler designs.

PCB Testing and Quality Assurance:

Comprehensive testing and quality assurance processes are essential to ensure the reliability and performance of high-tech PCBs. Thorough testing, such as automated optical inspection (AOI) and in-circuit testing (ICT), don’t usually add additional time to the production schedule. However, certain quality requirements such as AS9100 documentation or outside lab certification of cross sections or coupons can add significant time to the delivery.

Manufacturing Complexity and Special Requirements:

Some high-tech PCBs may have specific manufacturing complexities or special requirements, such as advanced materials, specialized surface finishes, or a unique combination of manufacturing steps that cannot be done faster. These factors can extend the lead time as they often involve additional steps or require specialized equipment and expertise.

High-Tech PCB Manufacturing

While all these items do add lead time to the manufacturing process when we work closely with customers prior to the order being started we can usually work around these issues and hit the critical deadlines that our customers need.

In the realm of high-tech PCB manufacturing, NetVia Group stands tall as the number one choice for quick turnarounds. With our unwavering commitment to customer satisfaction, cutting-edge